Product Description

Our sublimation printer VS-901HTP/1601HTP offers one-stop printing solution, releasing users from the heat transfer paper printing jobs and the printing troubles. It is no longer difficult to accomplish the high volume inking performance.

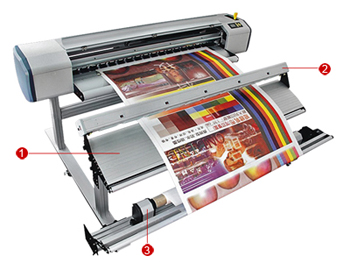

1. The unique back heating platform can drying and ironing the heat transfer paper with high-efficiency. More smooth paper, better heat transfer quality.

2. Hot Wind Dry System, Hot-win and Cold-win fits different printing speed.

3. Take-up System with Tension Control Function

This machine is mounted with only one Epson DX5 head, exerting outstanding printing effect on various heat transfer papers. Under 4 colors mode, it is able to print at the speed of 15m²/h to the upmost.

Application

1.Printing on clothing, curtain, sofa, umbrella, handbag, carpet, toys, etc.

2.Printing decoration on plastic surface of heat resistant plastic materials, plastic materials after coating, painting and electrophoresis, etc.

3.Printing decoration on metal surface of metal decorative plates after coating painting, etc.

4.Printing on the pros and cons of natural leathers

5.Printing on the surface of PU, PVC and materials coated PU/PVC, etc.

Advantages

1.Professional Print for Digital Transfer Paper

This sublimation printer makes full use of the printing technology with CMYK×2 colors. It offers continuous printing on a whole roller without any guards. Equipped with the particular drying and tensioning system, this device is capable of printing the media for 2,000m without scarping nozzles and corrugating printed medium in the entire process.

2. Rapid Drying

Our product employs double heating systems for drying the medium at high speed. One is a 300mm wide back drying platform with the temperature ranging from 60 to 70°C. It makes the medium ironed completely and increases the rate of finished printed product. The other system is the heating platform with hot air dryer. Both the cold air and hot air dryers are available under segmented control.

3. Precise Medium Tensioning and Feeding

The constant tensioning and feeding system gets the transfer paper tense without any deviation.

4. Efficient Cost Reduction

Compatible with any brands of transfer paper, the sublimation printer makes its print head durable without scratches. As the cheap heat transfer paper is still available, it saves much use cost for users. In addition, the optimal drying and tensioning system not only raises the rate of finished product, but also lessens the scrap rate as possible as could.

| Model | VS-901HTP | VS-1601HTP | ||

| Print Head Technology | DOD micro piezo head, 180 nozzles ×8 lines | |||

| Print Head Quantity | 1pcs | |||

| Max. Printing Width | 920mm | 1620mm | ||

| Resolution | 360DPI, 720DPI, 1080DPI, 1440DPI | |||

| Printing Speed | Production 4Pass | 12m²/h | 15m²/h | |

| Standard 6Pass | 10m²/h | 12m²/h | ||

| Quality 8Pass | 8m²/h | 10m²/h | ||

| High Quality 12Pass | 5m²/h | 6m²/h | ||

| Ink | Type | Water base dye sublimation/disperse ink, reactive ink, acid ink | ||

| Color | 2×CMYK | |||

| Supply Way | Refillable cartridge, optional continuous ink supply system | |||

| Capacity | Standard 220ml×2/color | |||

| Fabric | Media Type | Heat transfer paper | ||

| Media Feeding | Passive | |||

| Max. Media Width | 940mm | 1640mm | ||

| Max. Media Load | Passive 25kg | |||

| Max Media Diameter | 350mm | |||

| Print Head Height | From media surface 1.5, 2.0, 2.5, 3.0 adjustable | |||

| Print Head Cleaning | Auto purging and capping system | |||

| Auto Media Tensioning | Inductive tensioning system | |||

| Media Drying | Back heating and hot air drying system (segmented control) | |||

| Interface | USB 2.0 | |||

| RIP Software | Standard Main Top RIP, PhotoPrint, Wasatch and other third-party software. | |||

| Operation System | Windows XP, Win7 | |||

| Power Consumption | 220VAC/50Hz +- 10%, Max. 10A | |||

| Environment | Temperature: 20ºC~32ºC Relative humidity: 40%~ 80% | |||

| Package Size: L×W×H/Weight | 1710mm×782mm×1170mm/ 100kg | 2410mm×782mm×1170mm/130kg | ||

Related Names

Dye Sublimation Printer | Heat Transfer Paper Printer